Stop valves

Read more

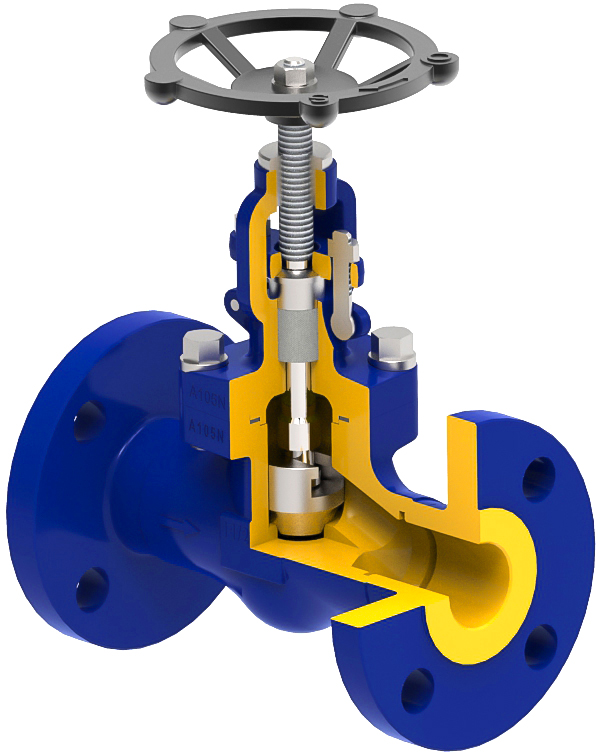

Stop valves are essential components in pipeline systems where full shut-off of the medium is required. Their robust design ensures reliable operation in a wide range of industries, from energy and shipbuilding to chemical and petrochemical plants. Manufactured in multiple material versions and pressure classes, these valves are adapted to diverse operating environments, including installations with high pressure and temperature demands.

Depending on the design, they can withstand conditions from −60°C up to +550°C and pressures from PN 6 to PN 160 or ANSI Class 150 to 600. Tested in accordance with EN 12266-1, and in selected cases API 598, stop valves provide high tightness and operational safety. Their compliance with European and international standards makes them a dependable choice for both new projects and existing systems that require proven reliability and compatibility.

Construction and materials

The stop valve range includes forged steel, cast steel, stainless steel, alloy steel, grey cast iron, and nodular cast iron variants. This diversity allows engineers to select the right solution for specific media and operating conditions. Internal elements, such as stems and discs, are often made of stainless steel to provide increased resistance to wear and corrosion. Depending on the series, cover gaskets may use steel–graphite combinations to ensure reliable sealing even under high thermal stress.

Pressure and temperature performance

Stop valves are available in a wide spectrum of pressure ratings, from PN 6 to PN 160, as well as ANSI Classes 150, 300, and 600. They are designed for working media under temperatures as low as −60°C and as high as +550°C, depending on the valve figure and body material. The combination of precise machining and robust materials ensures stability in long-term use. Each valve is factory tested to EN 12266-1 for tightness, which guarantees leakage-free performance in industrial applications.

Standards and end connections

The valves conform to recognized European and international standards for installation and integration. Depending on the figure, flanged ends follow EN 1092 or ASME B16.5, while face-to-face dimensions correspond to EN 558, DIN 3202, or ASME B16.10. For welded connections, EN 12627 applies. This compatibility allows easy integration into both European and international piping systems, ensuring flexibility during system design or modernization.

Operation and actuation

Stop valves are typically operated manually by means of a handwheel, providing straightforward and reliable control of the medium. Certain designs are also available with bare shafts or can be equipped with electric actuators, enabling remote or automated operation. This flexibility makes them suitable for both conventional systems and advanced installations requiring higher levels of control.

Applications

The versatility of stop valves allows them to serve in a wide range of industries and processes. They are applied in power engineering, chemical and petrochemical plants, shipbuilding, heating systems, and refrigeration or air-conditioning installations. Depending on the selected material and pressure class, they are suitable for handling glycol, industrial water, diathermic oil, steam, compressed air, natural gas, and other neutral or moderately aggressive fluids. Medium compatibility must always be verified according to the material specification.

Certified quality and compliance

Stop valves are manufactured in accordance with the Pressure Equipment Directive 2014/68/EU, with CE marking applied for nominal diameters from DN 32 upwards. Their design emphasizes high tightness, durability, and environmental protection, ensuring safe and long-lasting use in demanding industrial conditions. The combination of rigorous testing and compliance with international standards confirms their role as dependable shut-off devices across multiple sectors.

Long-term reliability for demanding industries

Stop valves stand out as reliable and durable shut-off devices that meet the strict requirements of modern industry. Their wide material range, extensive pressure and temperature capabilities, and compatibility with international standards make them highly adaptable to various applications.

Whether used in energy production, chemical processing, or shipbuilding, they ensure safe handling of different media, from steam and compressed air to natural gas and industrial water. The combination of precise construction, factory testing, and compliance with the Pressure Equipment Directive provides confidence in long-term performance. Thanks to their versatility and certified quality, stop valves remain one of the most widely used and trusted elements of industrial pipeline systems.