Static balancing valves

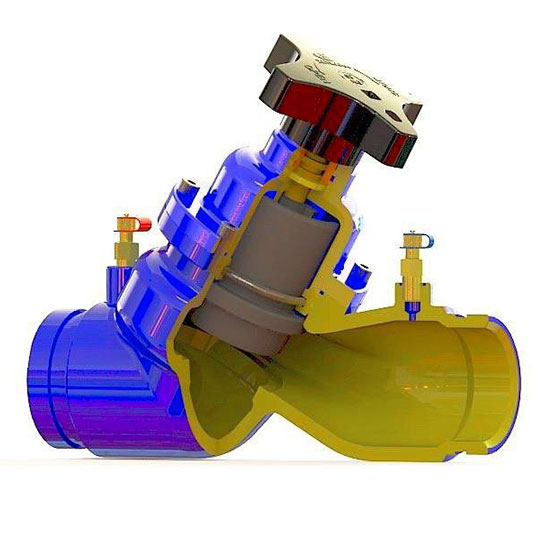

ZETKAMA zSTA is a line of industrial components for various air- and waterflow systems. The main function of static balancing valves is to maintain proper pressure in the pipework. Such elements not only allow for manual regulation of the flow rate, but are also used for taking precise measurements and controlling the performance of the infrastructure. The areas in which such components are applied include heating and air conditioning installations, as well as other pneumatic and hydraulic industrial systems.

Static balancing valves – optimal safety and control

There are numerous options in terms of construction and extra functions within the ZETKAMA zSTA series. We provide models equipped with high-reliability measurement devices – both analog and digital – as well as precise and ergonomic handwheels for maximum control. The materials we use range from brass to grey and nodular cast iron. Technical specification, catalog sheet and user manuals for a given model are included in the respective offer.

Read more

Static balancing valves are essential components in water-based heating and cooling systems, designed to ensure permanent hydraulic balance within closed circuits. By allowing precise manual adjustment of flow, these valves play a key role in commissioning and maintaining the correct performance of HVAC and industrial fluid systems. Their application ensures that every branch or terminal unit receives the intended flow rate, contributing to energy efficiency, comfort, and system reliability.

Hydraulic Balance Through Manual Control

Static balancing valves enable installers and engineers to set a fixed resistance in a system, thus defining a constant flow rate. This is especially important in systems where uniform fluid distribution is critical for maintaining consistent performance—such as in heating networks, chilled water systems, and glycol loops.

Once adjusted, the valve maintains the set flow rate regardless of pressure fluctuations elsewhere in the system. This is achieved through manual throttling and a calibrated internal geometry, typically using a Venturi insert that guarantees predictable differential pressure and repeatable measurement values.

Integrated Measurement Features

Many static balancing valves feature integrated pressure test ports, which allow technicians to measure differential pressure across the valve using standard instruments. This functionality is invaluable during system commissioning, enabling real-time verification of flow rates without requiring the installation of external measurement devices.

The use of a calibrated DZR brass Venturi insert (in smaller valve models) enhances measurement accuracy and ensures consistency across installations. Some valves also include a 40-position hand-wheel with a memory stop function, enabling the previously set position to be restored after maintenance or servicing.

Robust Construction and Standard Compliance

Static balancing valves are available in a variety of sizes, with body materials tailored to different applications. For small to medium pipelines, brass models offer corrosion resistance and precise control. For larger installations, cast iron versions provide structural durability and compatibility with industrial piping systems.

These valves comply with several key standards:

- Leak tightness and pressure testing: in accordance with EN 12266-1

Flange connections: available as per EN 1092-2 or ASME B16.1 (Class 125)

Face-to-face dimensions: compliant with EN 558, series 1

All valves in this category are operated manually, without the use of actuators.

Wide Range of Applications

Static balancing valves are suited to a range of systems and operating conditions, including:

- Heating circuits requiring precise control of flow through risers and terminal units

Chilled water systems, where flow imbalance can lead to issues such as coil hunting or inconsistent temperature control

Glycol-based circuits that need stable flow distribution after partial draining or refilling

General industrial applications involving neutral fluids, where flow limitation and pressure tapping are needed for routine diagnostics

Their versatility makes them a practical choice in both commercial and industrial settings.

Enhancing System Efficiency and Reliability

By ensuring a balanced distribution of media throughout the network, static balancing valves contribute to reduced energy consumption, extended system life, and greater control over operational parameters. The ability to verify flow using integrated test points not only speeds up the commissioning process but also supports ongoing maintenance and system diagnostics.

In environments where fixed flow regulation is a design priority, static balancing valves offer a durable and reliable solution that supports efficient system performance over time.

Mechanical Precision for Demanding Applications

Static balancing valves provide a straightforward, mechanical method of achieving flow balance in closed-loop fluid systems. Built according to rigorous manufacturing standards and equipped with features that simplify adjustment and verification, they represent a dependable choice for engineers, installers, and system operators seeking stable, long-term flow control without reliance on dynamic components.