Safety valves

Safety Valve

Selection

Read more

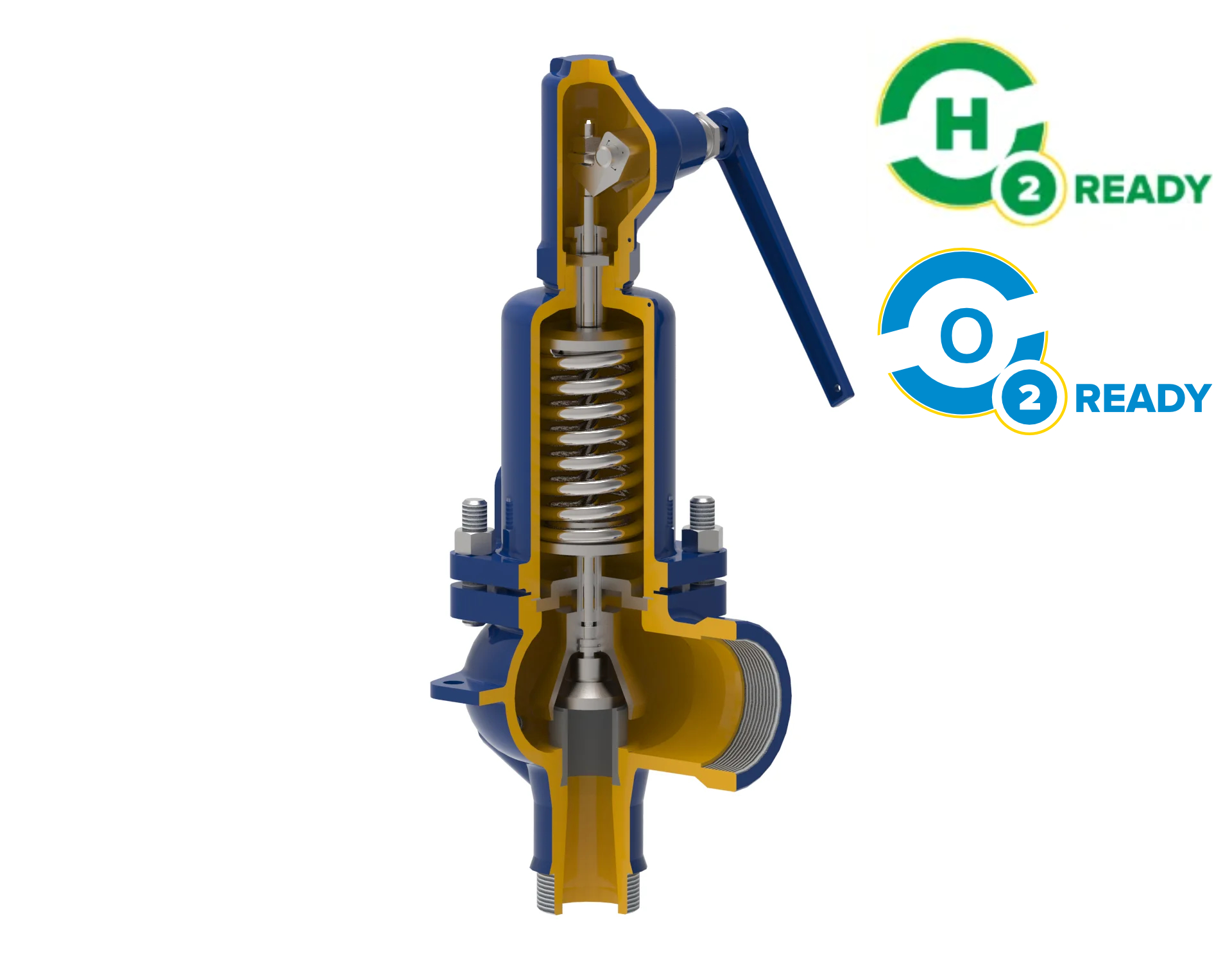

Safety valves are critical components in modern industrial systems, designed to ensure reliable protection against excessive pressure. Their function is simple but vital: when the pressure in an installation exceeds a defined limit, the valve opens automatically to release the medium and restore safe operating conditions. This protective mechanism prevents potential equipment failures, reduces the risk of accidents, and helps maintain continuity of technological processes.

Within this category, the range includes spring-loaded full-lift safety valves as well as proportional safety valves. Both types are manufactured in accordance with internationally recognized standards such as API 526, ASME Section VIII, and EN ISO 4126-1, and may carry approvals and markings including ASME UV, CE (PED), and UKCA.

This ensures that the valves are accepted worldwide across industries where operational safety and regulatory compliance are mandatory. Their versatility, supported by a wide choice of pressure ratings, body sizes, and material executions, allows them to be used in highly demanding environments, including applications at cryogenic temperatures or in high-temperature processes.

Design and Operating Principles

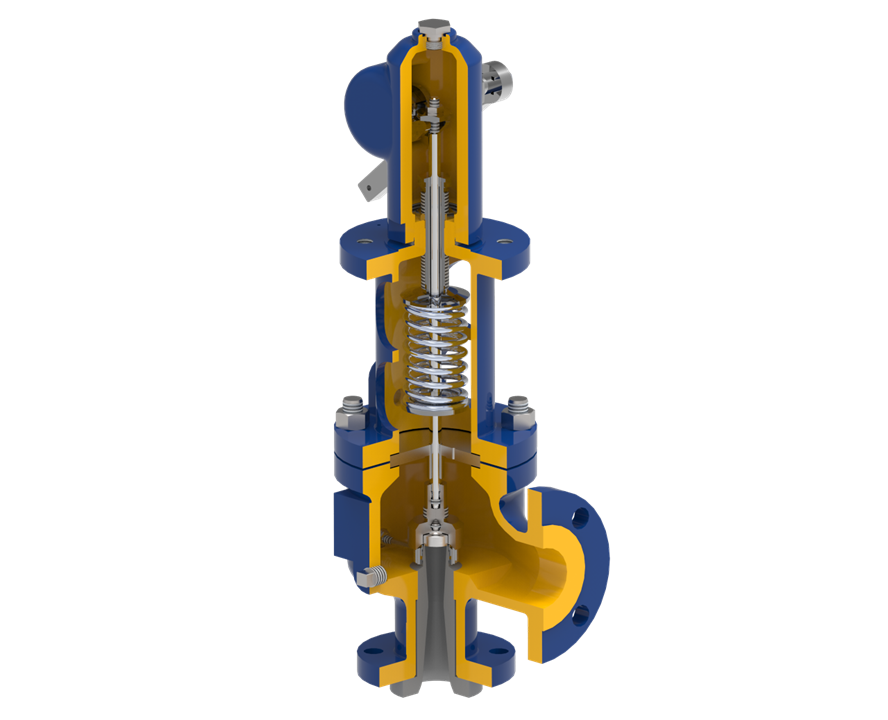

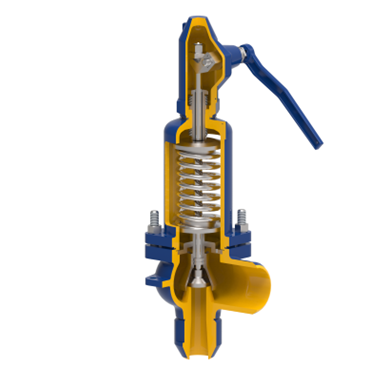

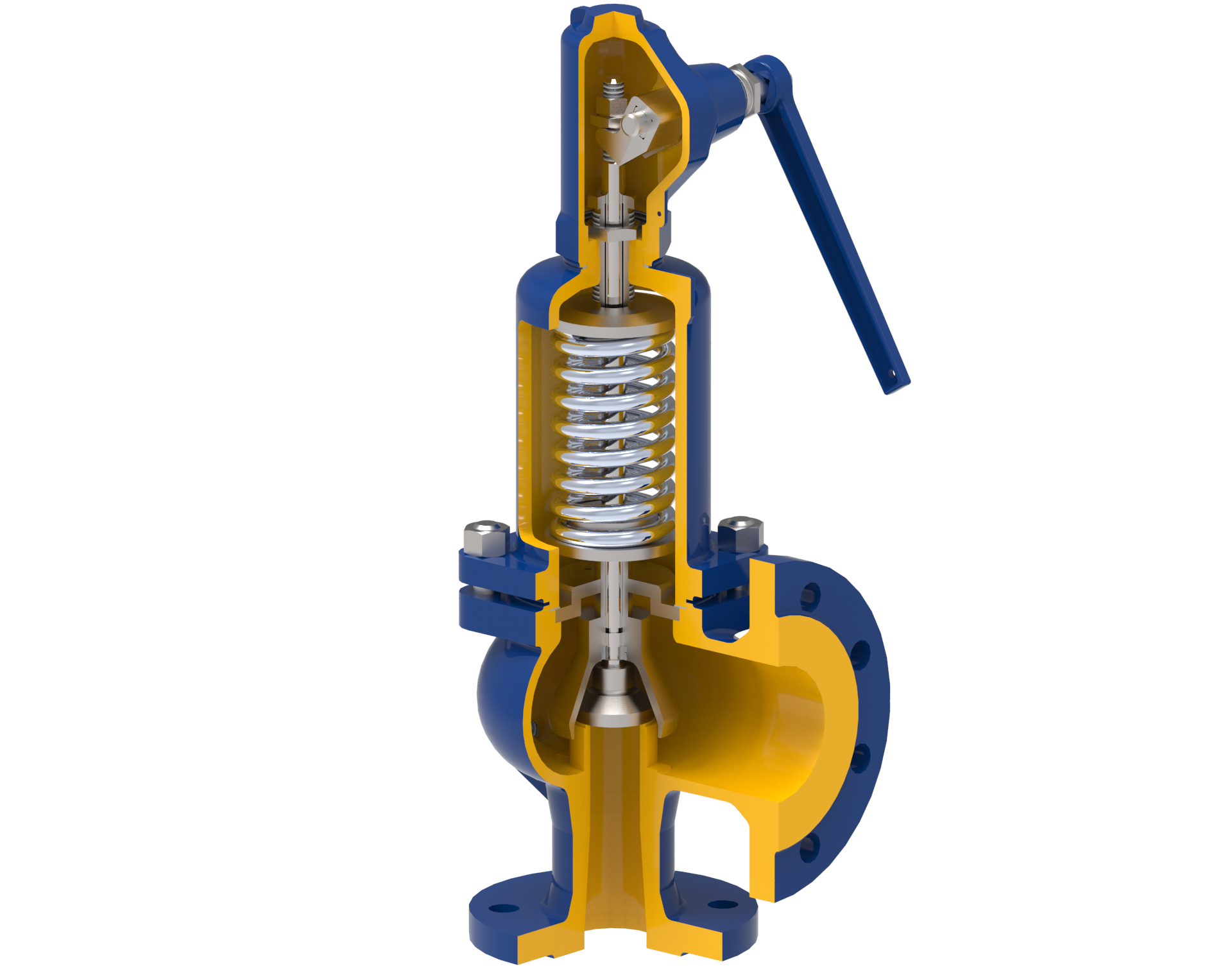

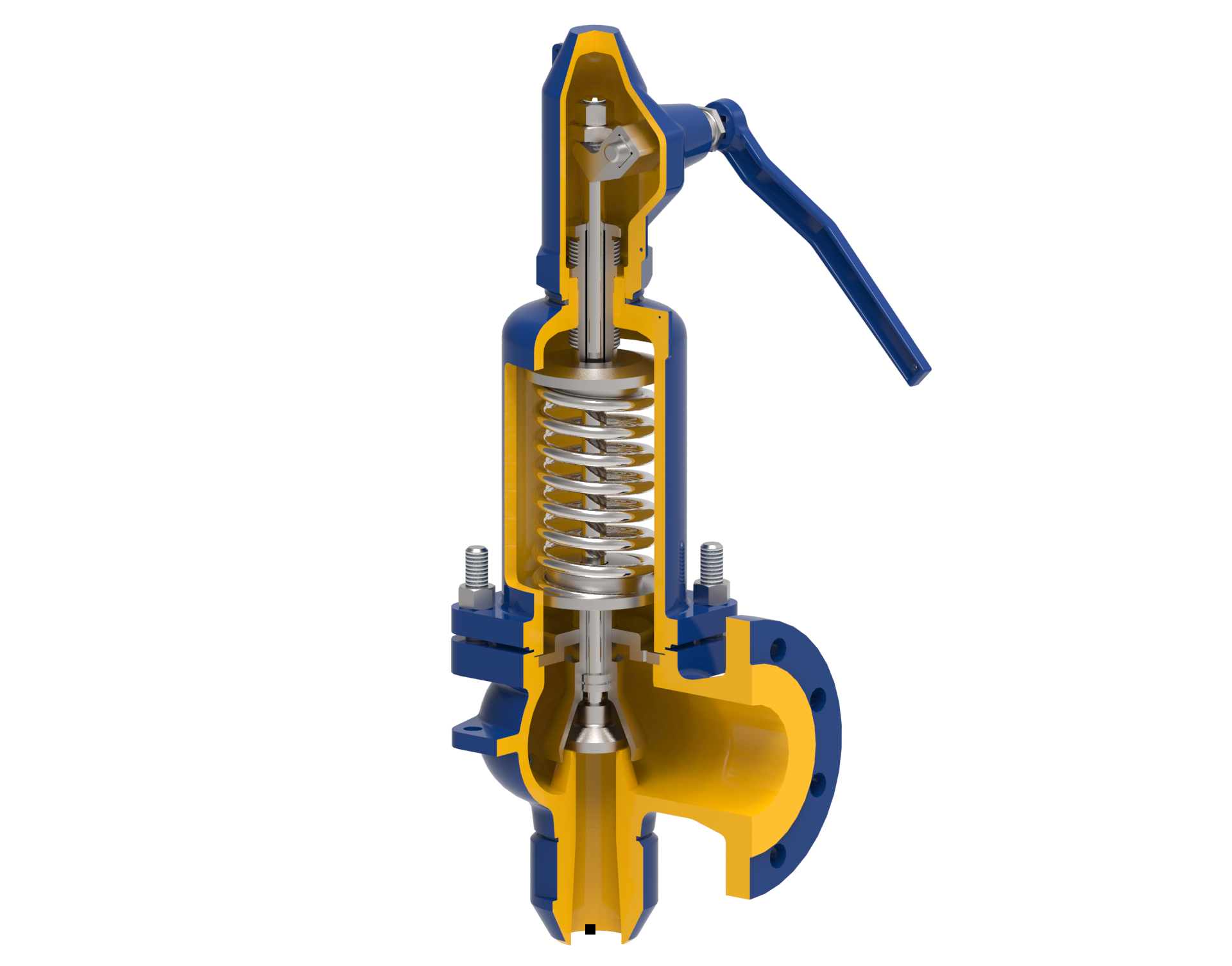

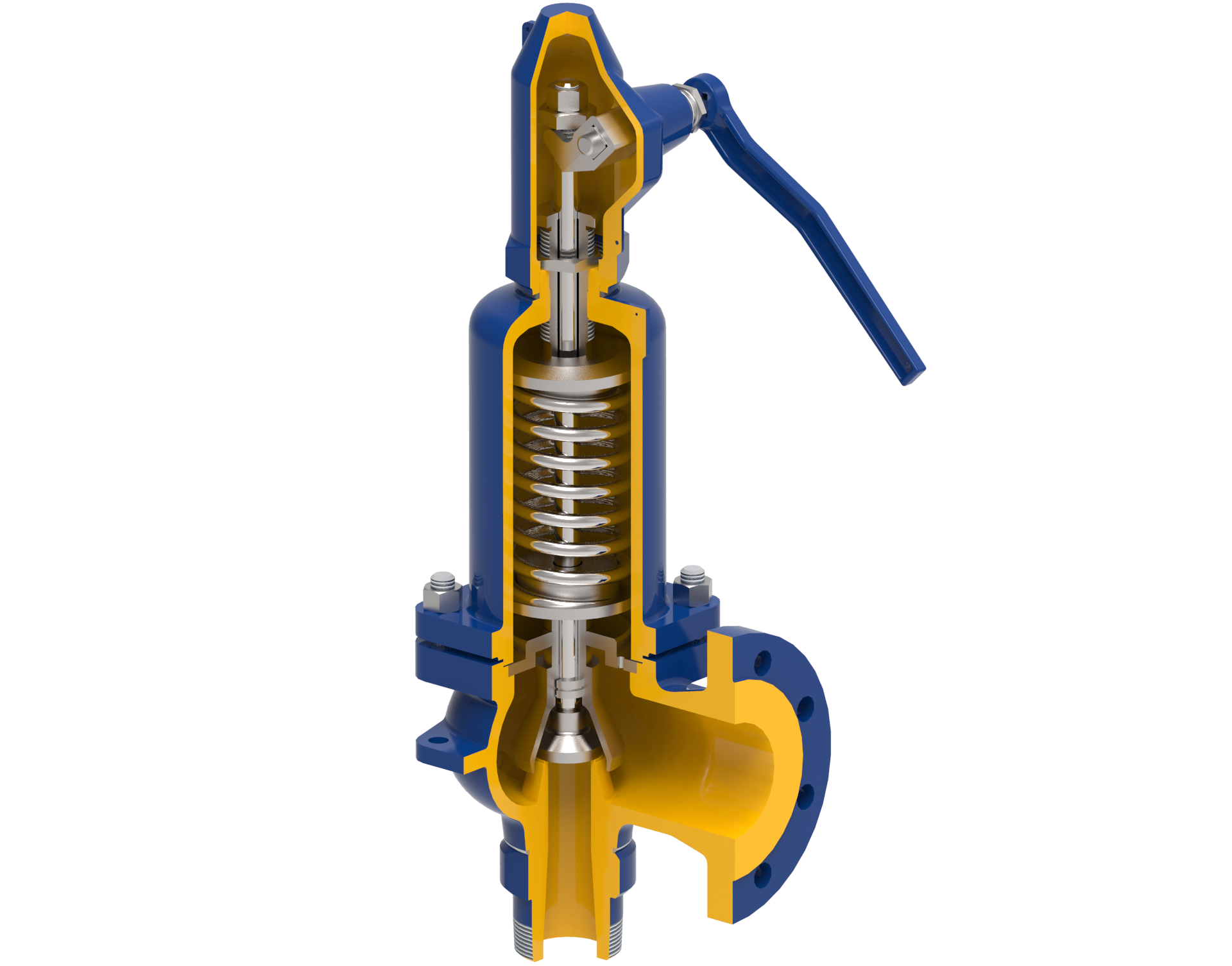

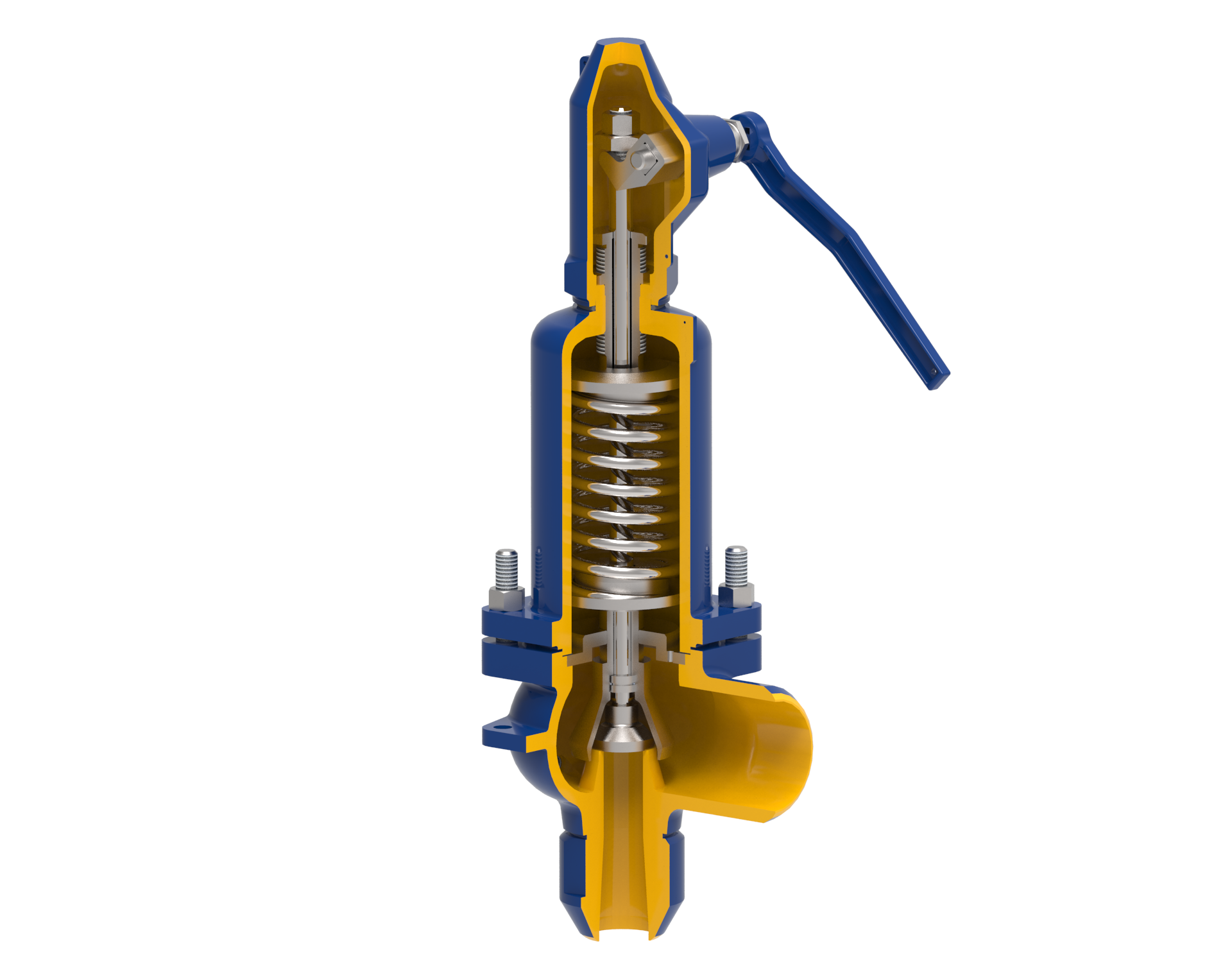

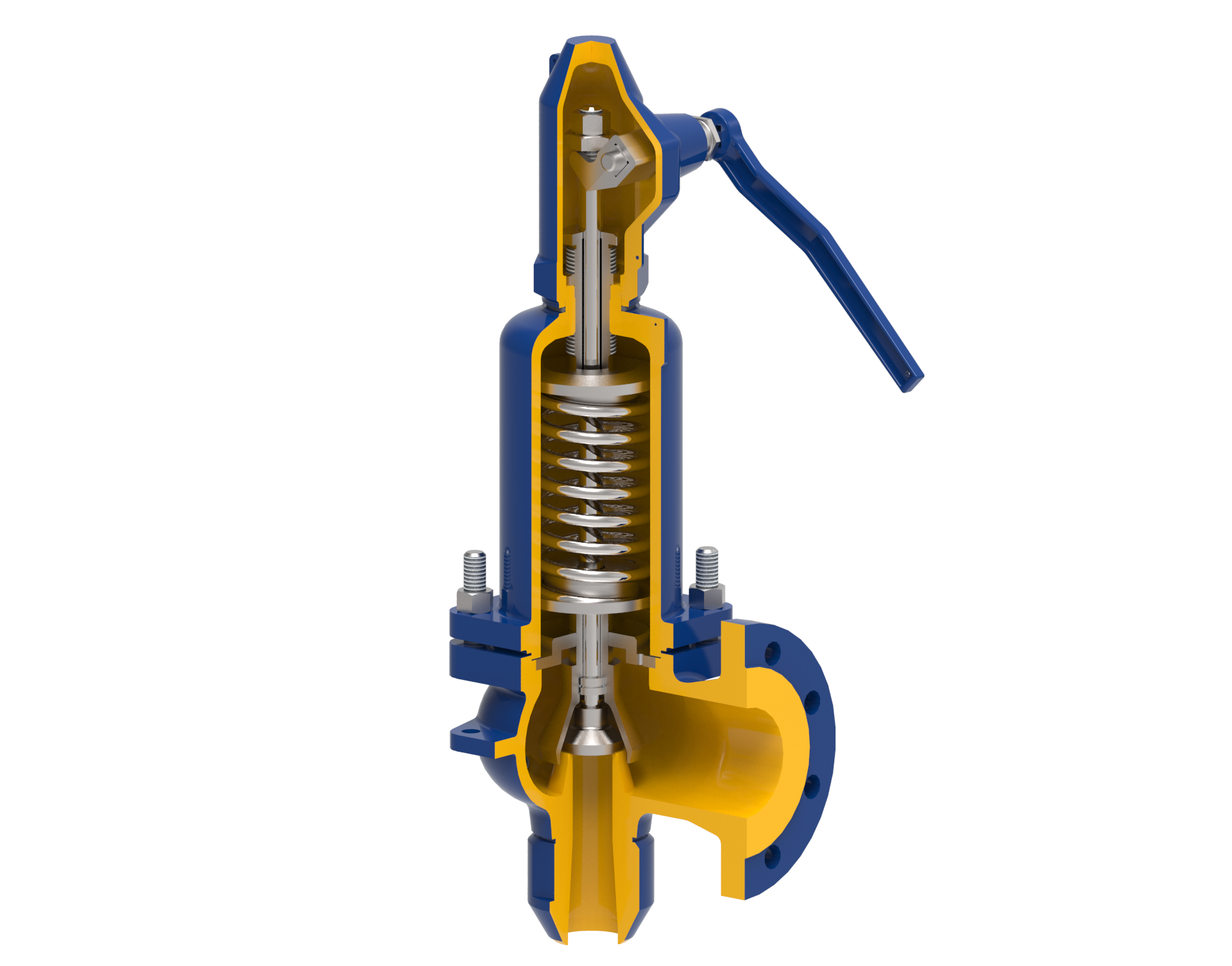

The category covers valves in pressure ratings ranging from PN 40 to PN 100 and ASME Classes 150–600. The construction follows standardized orifice series and flange connections, which ensures compatibility with international piping systems. Depending on the execution, the valves may be fitted with features such as open or closed bonnets, lever-operated or sealed caps, bellows to compensate backpressure, stellited sealing surfaces, or inductive sensors that enable remote monitoring of the valve’s lift.

The operating principle is based on a calibrated spring force. Once the system pressure reaches the set value, the spring is compressed and the disc lifts, releasing the medium. In the case of full-lift safety valves, the valve achieves full opening shortly after the set pressure is exceeded, which guarantees rapid discharge capacity. Proportional safety valves, on the other hand, open gradually in proportion to the rising pressure, providing controlled relief.

Materials and Temperature Ranges

To cover diverse process conditions, safety valves are available in materials such as carbon steel (WCB), alloy steel (WC6), and stainless steel (CF8M). These materials extend the applicability of the valves across a wide thermal spectrum:

- WCB: −29 °C to +427 °C

- WC6: +427 °C to +538 °C

- CF8M: −196 °C to +538 °C

This ensures suitability for cryogenic service, standard industrial installations, and high-temperature environments. The internal components are manufactured with attention to wear resistance and sealing reliability, often including hardened or stellited surfaces.

Standards and Certification

Compliance with API 526 and ASME Section VIII is crucial for many industrial users, and selected valves within this category are supplied with ASME UV marking, confirming that their discharge capacity has been tested and certified. They also meet the requirements of the Pressure Equipment Directive (PED 2014/68/EU) for CE marking and the UK Pressure Equipment Safety Regulations (UKCA). Manufacturing in accordance with EN ISO 4126-1 ensures harmonization with European safety requirements.

Applications

Safety valves in this category are suitable for a wide range of media, provided that the chosen material is compatible with the working environment. They can be used for steam, gases, compressed air, hydrocarbons, oils, glycol, water, sewage, and chemical fluids. As a result, they are applied across multiple industries, including energy and power generation, petrochemicals, shipbuilding, chemical processing, refrigeration and heating systems, pharmaceuticals, and general industrial installations.

Selection Parameters

Correct sizing and selection of a safety valve require several key parameters to be defined. These include the set pressure, static backpressure (constant or variable), required discharge capacity, and detailed information about the medium, such as density, viscosity, and operating temperature. Using this data, valves can be matched precisely to the system requirements, ensuring optimal protection and compliance with standards.

Ensuring Reliable Overpressure Protection

Safety valves are indispensable safeguards in industrial installations, acting as the last line of defense against the risks posed by overpressure. By opening automatically when limits are reached, they protect people, equipment, and entire processes from potentially dangerous failures. The availability of different designs, pressure ratings, and material executions ensures that the right solution can be tailored to almost any application, from cryogenic systems to high-temperature operations.

With certification to recognized international standards, these valves not only guarantee safety but also provide confidence in long-term reliability and regulatory compliance. For engineers and plant operators, selecting an appropriate safety valve means securing both operational continuity and the protection of valuable infrastructure.